Custom Screen Protector Supplier

Get the Perfect Fit with POWELL Custom Screen Protectors

At POWELL, we make custom screen protectors that are perfect for all kinds of electronic screens. We offer a versatile solution for electronic display screen manufacturers, screen protector brands, and wholesalers. Our screen protectors fit perfectly on phones, tablets, laptops, watches, and even car screens.

Our custom screen protectors are designed for precise fit and functionality. We provide options to customize dimensions, corner radiuses, and specific cutouts, ensuring each protector seamlessly matches the device it’s intended for. Want to make your protectors unique? We can add your logo or special designs.

How we produce custom screen protector

1. Measure custom screen protector dimensions

To kick off, measure your screen according to its type. This initial step ensures that the custom screen protector fits perfectly.

-

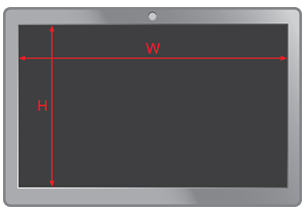

Raised Bezel

These screens have a raised frame around the edges.

Measure the height (h) and width (w) of the screen’s viewable area, making sure to measure within the bezel.

-

Flat Front Glass

These screens have an edge-to-edge glass without a raised frame.

Measure the height (h) and width (w) of the entire glass display, making sure to measure all the way from edge-to-edge.

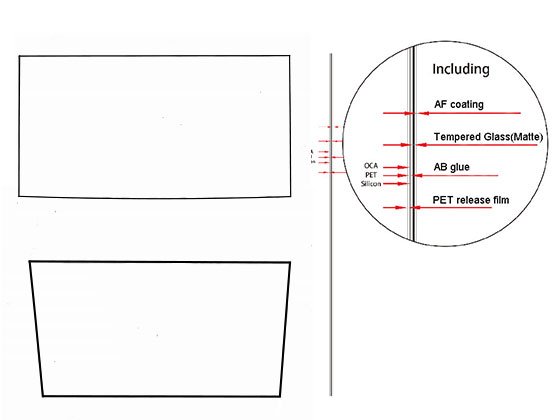

2. Scanning and Drawing

If your requirements differ from standard models, you have two options:

- Scanning: Provide a physical sample for us to scan and then draw.

- Drawings: Supply your design drawings, detailing height, width, and any necessary cutouts.

3. Select the right raw material

At POWELL, we offer a range of glass materials, categorized into three levels to suit various needs and budgets:

- Level 1 (Premium Quality): Includes Corning and Schott glass. Though more expensive, the quality difference compared to normal glass is minimal.

- Level 2 (High Quality): Features Asahi, Nippon, and High Aluminosilicate glass. A balance of quality and cost.

- Level 3 (Standard Quality): CSG glass, offering basic quality at a more affordable price.

We generally recommend Level 2 for its balance of quality and value, unless specific brand requirements or ultra-thin glass (0.15mm or 0.1mm) are needed.

- Japan AB Glue: Toyo and Nippa glues are known for their high quality and stability, with Toyo being the top choice.

- Korean AB Glue: There’s a wide range, with varying quality. Recent improvements in Korean glues have made them a popular, cost-effective option.

Brands: Daikin (Japan) is the leading choice for AF oil, known for superior quality. Other options include Korean and Chinese brands.

Concentration Ratio: Top Ratio (5‰): For special customer requirements.

Mainstream Products (2‰ and 3‰): These ratios provide good quality for most needs.

AF Layer Application Technology:

- Low (Manual Coating): Basic application method.

- Medium (Machine Spraying): More consistent than manual coating.

- Top (Plasma Electroplating): The highest quality application, ensuring even and durable coating.

At POWELL, we strive to offer a variety of high-quality materials and application methods to meet the diverse needs of our customers. Choose the combination that best fits your product requirements and budget.

4. Mold Creation

Based on your drawings, we custom-cut the glass. The AB glue is also custom-cut to match the glass dimensions, ensuring a seamless fit.

5. Sample Production

We create a few sample pieces for quality assurance testing, adhering to your specifications. As this involves custom-cutting glass and AB glue through various technological processes, it’s a meticulous and high-value step.

The production line process:

6. Quality Testing

At POWELL, we uphold the highest quality standards, recognized globally. Our 4-point QC system includes checks for:

- Appearance: Ensuring flawless visual quality.

- Performance: Verifying functional excellence.

- Finished Goods Inspection: Assessing the final product.

- Customer Satisfaction Assurance: 100% commitment to your satisfaction.

Check more about Powell quality testing and inspection standard.

Choose POWELL for your custom screen protector needs, and experience a blend of precision, quality, and customer-focused service.

POWELL Custom Glass Screen Protector Service

Case Study: Tailor-Made Screen Protectors for Unique Needs

Our Promise: Top Quality Products Every Time

At POWELL, we focus on giving our customers the very best. We work hard to solve tough problems in making and delivering our products. This way, we make sure everything we offer is of the highest quality, always meeting our customers’ needs. It’s what makes us stand out from the rest.

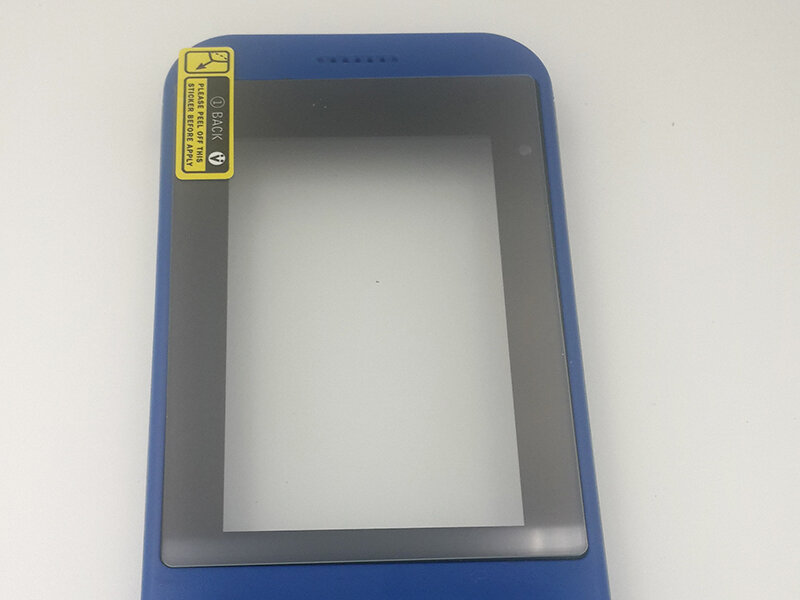

Glass Custom size screen protector for Antenna International

- Product model: ANTENNA-Audio-multimedia-player-xp3

- Size dimension: 95.3mm x 65.6mm

- Screen Protector Specification: 0.2mm Asahi Glass;

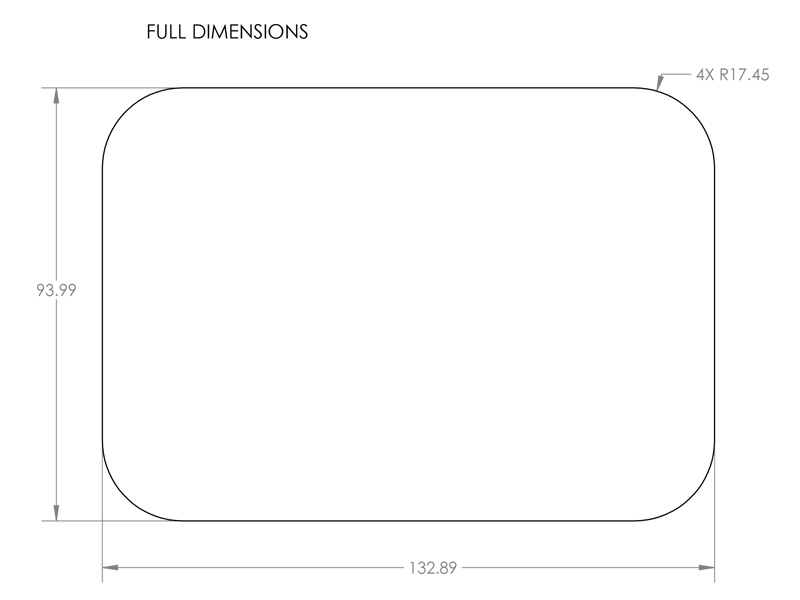

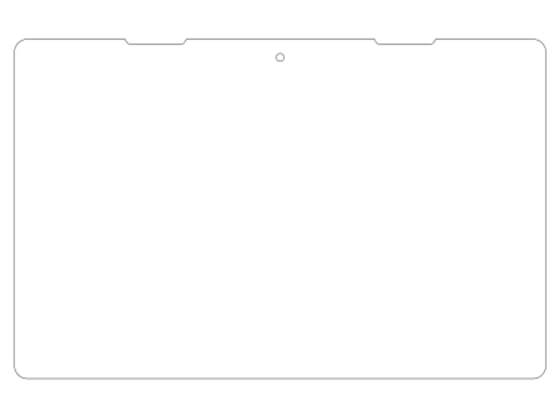

Custom screen protector(132.89 x 93.99mm) – For ERI Group

- Product model: ERI-01

- Size dimension: (132.89 x 93.99mm)

- Screen Protector Specification: 0.33mm CGS high aluminum glass

Glass custom screen protector for SCORA

- Product model: digital music stands-SCORA-Solo tablet (13″ Android tablet)

- Size dimension: 220X337mm

- Screen Protector Specification: 0.33mm Nippon Glass; Anti-glare (Matte)

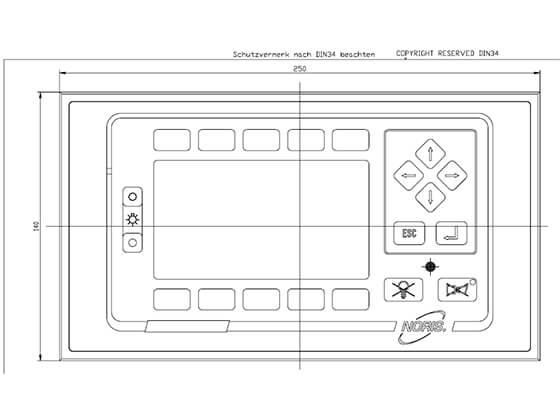

Custom glass screen protector for NORIS

- Product model: The master display for NORIS-automation components- N3000-DMP30/31

- Size dimension: 122X216mm

- Screen Protector Specification: 0.33mm Asahi Glass

Glass custom screen protector for Audi Q7

- Product model: for Audi Q7 upper screen and the bottom screen

- Size dimensions: upper screen 10″ and bottom screen 9″

- Screen Protector Specification: 0.33mm CSG glass- Matte Anti-glare

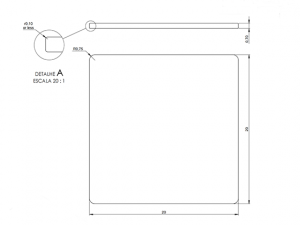

Glass custom screen protector for Eldorado

- Product model: for Eldorado PEÇA03

- Size dimensions: 20x20mm, R0.75mm

- Screen Protector Specification: 0.33mm CSG glass

Custom Glass Screen Protector Service

The additional function for glass screen protector

Anti-Spy (Privacy) glass screen protector

Custom-size privacy and protection to fit almost any screen. Powell offers custom-size solutions for privacy and protection on larger displays.

Powell privacy and protection screen protectors are custom-cut to work simply and suitable for most smartphones to help protect screens from everyday scratches and help keep the information displayed in private.

With these privacy-focused screen protectors, you can keep your information private while giving your phone’s screen some extra protection.

This Privacy Screen Protector keeps your personal, private, and the Screen is only visible to persons directly in front of the screen.

Easy to apply and remove, takes advantage of LG privacy technology. that made our privacy products work so well and become so popular.

Powell Custom-Size Black Privacy Glass Screen Protector

- Effective shading privacy from side views outside the 60-degree viewing angle

- Made with LG privacy AB glue, the top quality on Anti-spy

- Incredible image clarity in the center viewing angle

- Provides an extra layer of protection from dust and scratches

- Custom fit for various phone sizes and brands;

- Available for display up to a 15″ diagonal

Anti-glare (Matte) glass screen protector

Powell custom-size Anti-Glare screen protector improves screen sharpness and visibility with Anti-Glare Solutions.

Don’t let bright light and reflections get between you and your screen. Amazing optical technology from POWELL mirror-like reflections to help keep what’s on your screen clear and visible.

- Diffuses bright light and helps reduce glare

- Compatible with most touchscreen displays

- Gives screens a layer of added protection from dust and scratches.

- Matte surface cleans easily and hides fingerprints

- Available for monitors up to a 15″ diagonal